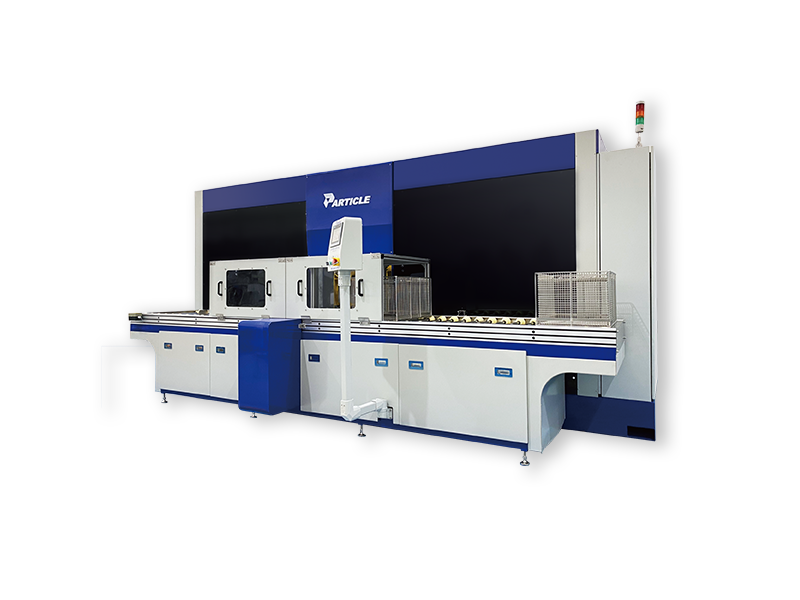

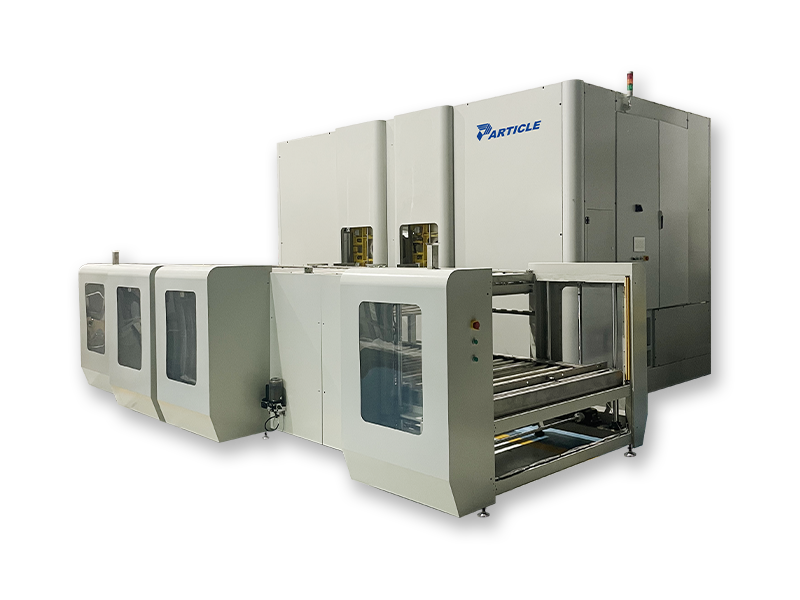

Automatic multi-tank Hydrocarbon cleaning equipment

- Commodity name: Automatic multi-tank Hydrocarbon cleaning equipment

Description

The automatic multi-tank hydrocarbon cleaning machine is an efficient, environmentally friendly, and automated cleaning equipment. It utilizes hydrocarbon solvents and features a multi-tank design to carry out processes such as cleaning, rinsing, and drying. It is easy to operate, energy-saving, and environmentally friendly, with excellent cleaning results. It is an important piece of equipment in modern industrial production.

Feature

· Multi-station distributed cleaning, fast cleaning speed

· Indirect heating system, safe and stable

· Vacuum, degassing, ultrasonic and other processes

· Cleaning solvent recycling, no need to replace the solvent

· Continuous on-line filtration to ensure the cleanliness of solvent

· Cleaning basket can be rotated, thrown, swinging

· Dewatering solvents can be selected to effectively remove water from the workpiece.

· Compatible with alkanes, alcohols and ethers and other organic solvents

· Organic solvents have their own short-term anti-corrosion ability

· Steam heating and vacuum drying, safe and efficient

· Can be equipped with multiple sets of drying stations to improve drying efficiency

· Powerful and flexible fully automatic robotic arm transfer system

· Equipped with automatic fire extinguishing system and explosion-proof electrical appliances

· Friendly HMI design, parameter status at a glance

· Supports Industry 4.0 technology, realizing data interconnectivity

Optional

· Rust-proof

· Cooling unit

· Concentration detector

· Exhaust gas treatment

Specification

|

Model |

Basket |

Tank |

Size |

|

PT-433-III-S |

480×380×386mm |

2 wash and 1 drying |

4600×2320×2600mm |

|

PT-654-IV-S |

600×500×400mm |

3 wash and 2drying |

5500×2450×2700mm |

|

PT-865-VII-S |

800×600×500mm |

5 wash and 2drying |

8550×2520×2800mm |

· Can be non-standard customized

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!