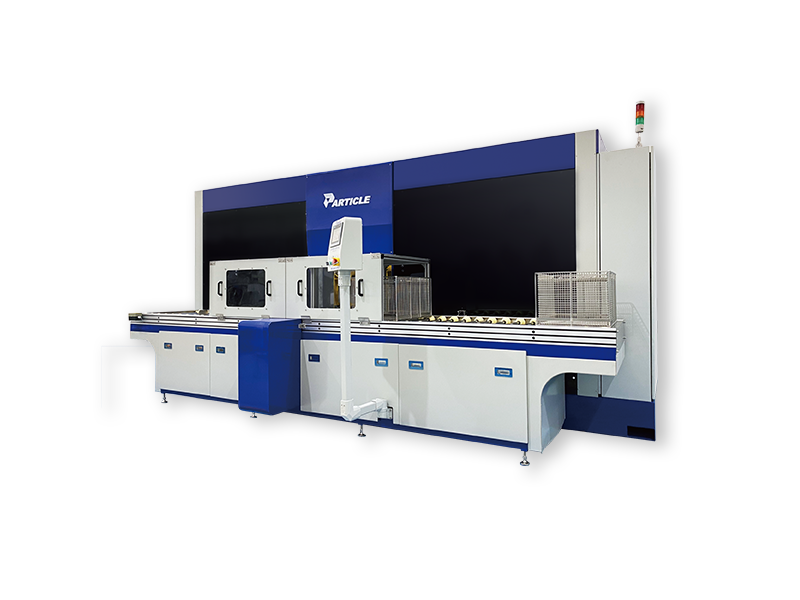

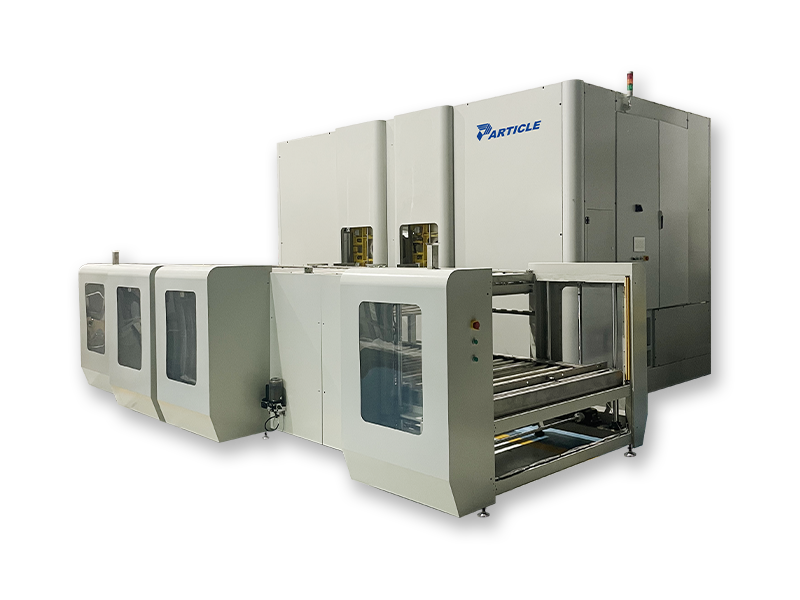

Description

Based on the mature technology of single-chamber systems, this equipment incorporates an innovative dual-chamber parallel architecture design. Through its intelligent chamber coordination control system, it achieves precision scheduling of cleaning processes. The dual working chambers alternately execute the complete cleaning-drying cycle, enhancing overall equipment efficiency by over 50% and establishing a new benchmark for precision component cleaning.

Feature

· One-stop solution for cleaning and drying

· Fully enclosed system for greater safety and environmental protection

· Compact footprint, high availability and easy maintenance

· Vacuum high-temperature rinsing demonstrates excellent degreasing capability

· Recycling of cleaning solvents, no need to replace solvents

· Heat recovery system ensures lower operating energy consumption

· Full drain circulating filtration ensures higher solvent cleanliness

· Steam, ultrasonic, spray, disturbed flow and other processes.

· The cleaning basket can be rotated or swing, and the swing angle can be set.

· Specialized in cleaning deep holes, blind holes, micro holes and deep grooves.

· Neutral solvents are suitable for all kinds of metal parts.

· Large flow rate and fast liquid discharge shorten the process time

· Siemens PLC control system is stable and reliable

· Friendly HMI design, parameter status at a glance

· Supports Industry 4.0 technology, realizing data interconnectivity

Keyword:

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!